Intra-oral scanners (IOS) play a central role in our daily clinical digital dentistry in our practice because we believe the future is now. One of the routine use of IOS is in our implant cases. Initially it was limited to planning guided surgery and fabrication of 3D guides and provisional prosthesis.

From making the initial impression of our implant cases for digital workflows, the scanner with its scanning protocol will ensure the most accurate digital impression. We are by passing the traditionally been an intra-oral impression that was subsequently poured in dental stone. Conventional traditional methods using silicone materials are difficult to apply in patients with a strong vomiting reflex, several unstable teeth, or trismus. This stone models are then used to produce frameworks for implant cases.

In this case a single implant crown screw-type restoration obtained by using digital intraoral impressions.

It captures single 3D frames that are stitched with other frames to compose a complete 3D model in a short registration cycle.

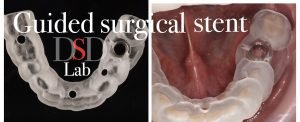

The introduction of cone beam computed tomography (CBCT), which can capture 3D information on bone anatomy with low doses of radiation, has greatly expanded the potential applications of guided surgery that we have been using widely in our practice . These applications now extend to teeth-supported surgical guides and therefore to cases where the planning requires placement of a lower number of fixtures.

We find that making impressions of implant cases for digital workflows, the technology from IOS gives a more accurate impression, bite registration, easier transmission of data to the digital dental laboratory where ever they are and most importantly the accuracy of the crown. Clearly, IOS and accompanying implant related technology [in the lab setting] provide better accuracy than building cases on stone models, plaster mountings, and resin-based adjuncts.

Yes, IOS can cut our chair time and the cost of traditional impression materials, only IF you have a compliant dental ceramist and laboratory.

Yes, IOS can cut our chair time and the cost of traditional impression materials, only IF you have a compliant dental ceramist and laboratory.

Otherwise the investment might be questionable. As clinicians we must consider support from our dental suppliers , in this case , the implant company . They must also embrace in technology like bringing in the guided surgical kit, its accessories such as the scan body for digital impression . We must also have partnering laboratory to be able to accept our STL and DICOM files and able to use and produce the prosthesis if we don’t have an in-house lab.

Without all these , it would be very challenging to consider investing in this technology because not all parties involve in dentistry are ready to evolve.

With regard to clinical application, it is expected to improve dental services by offering minimally-invasive, comfortable, and safe treatment procedures. These advantages may provide several benefits to dentists, dental technicians, and patients if the applications are not limited to software and production procedures.